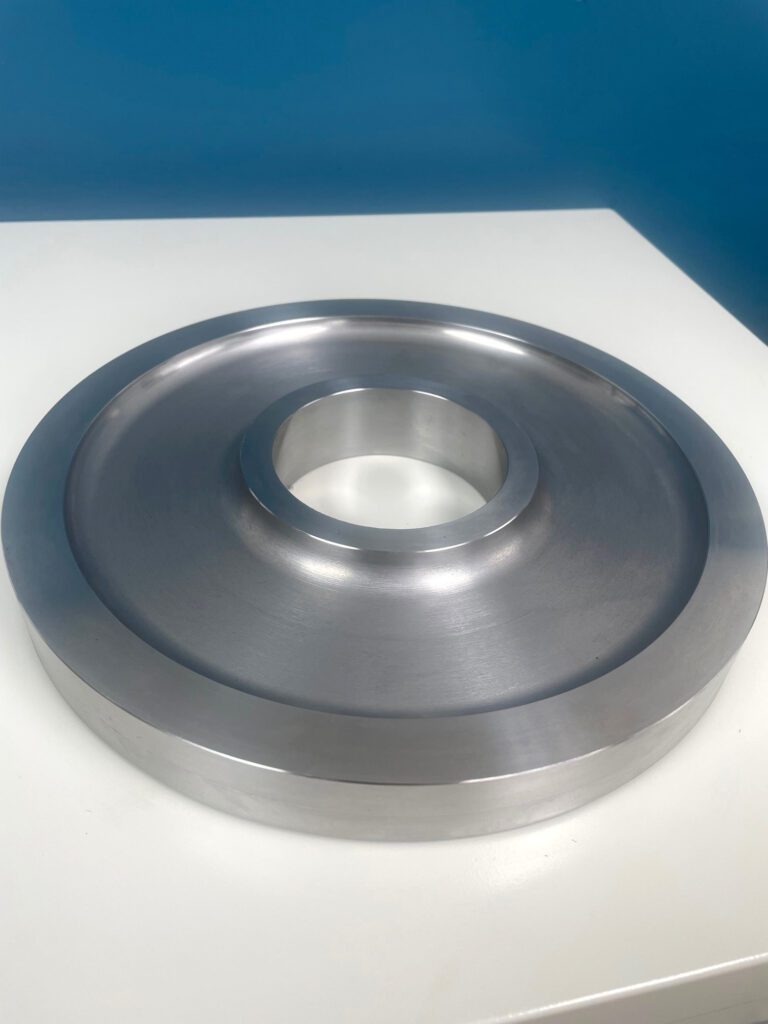

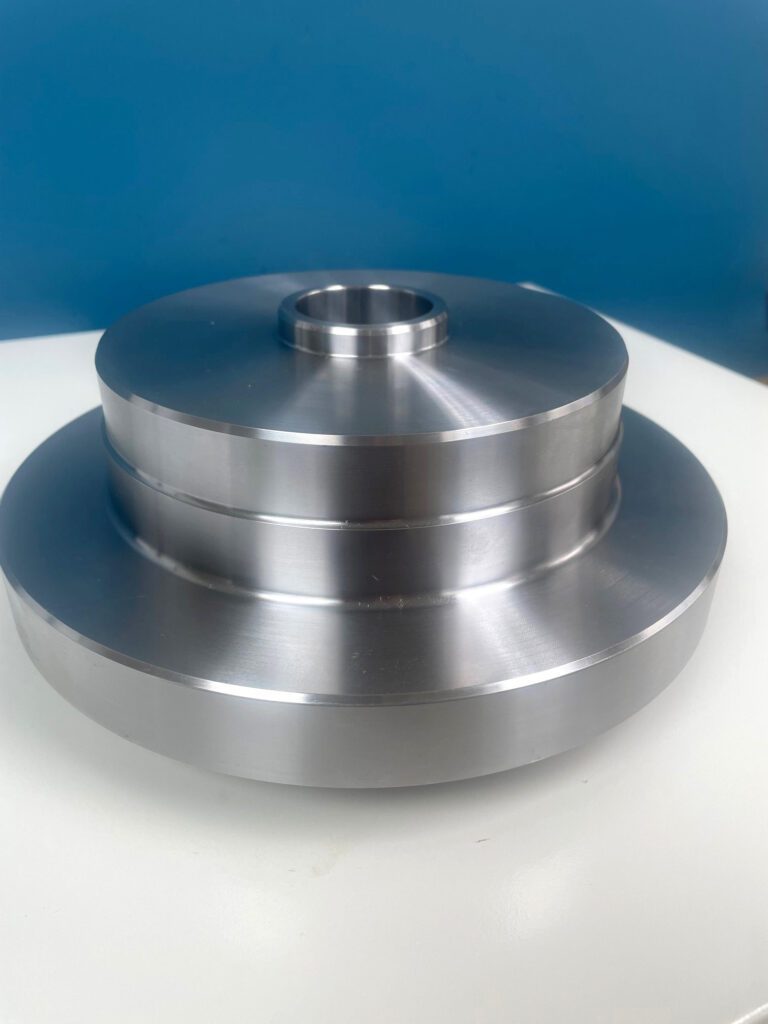

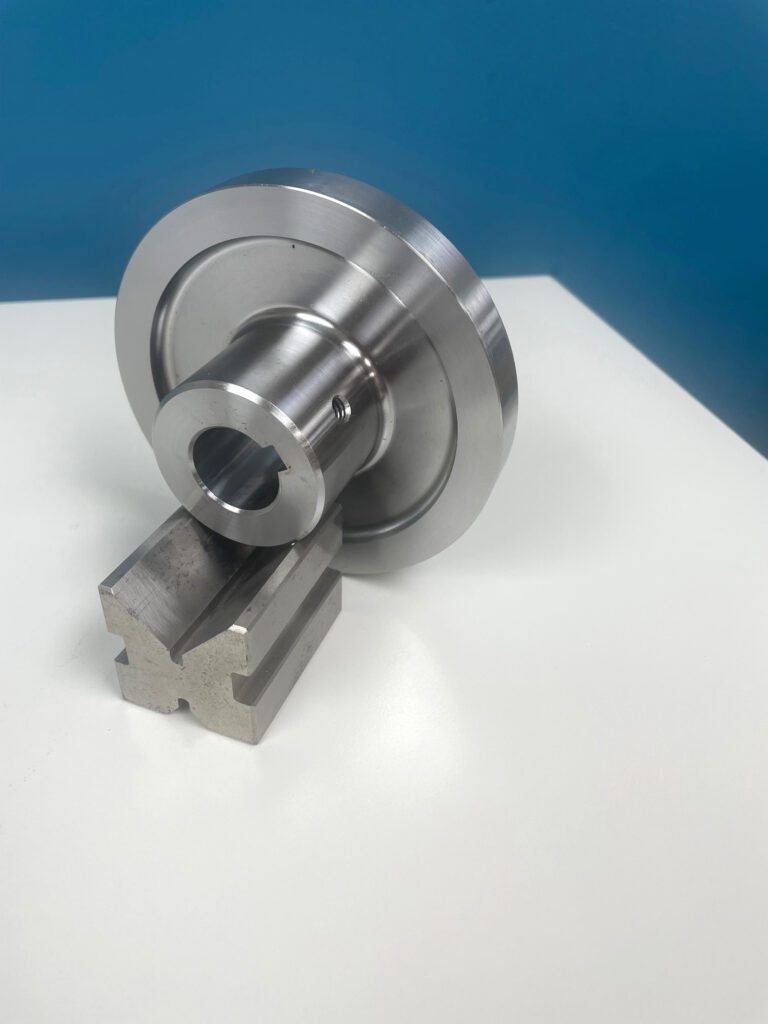

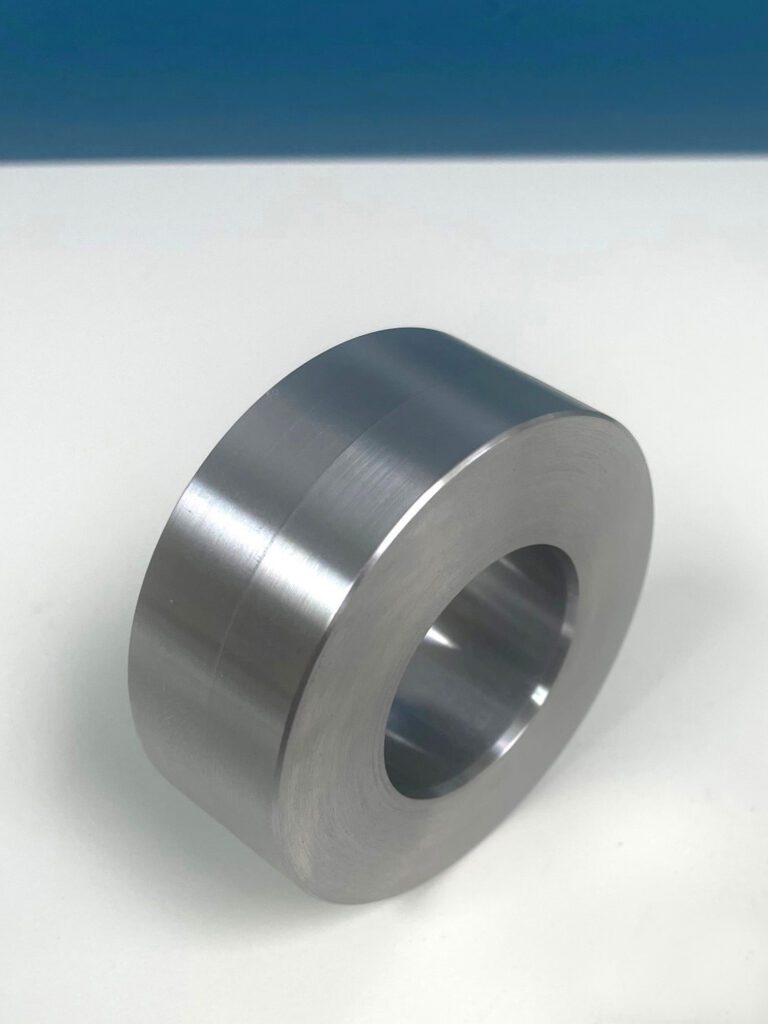

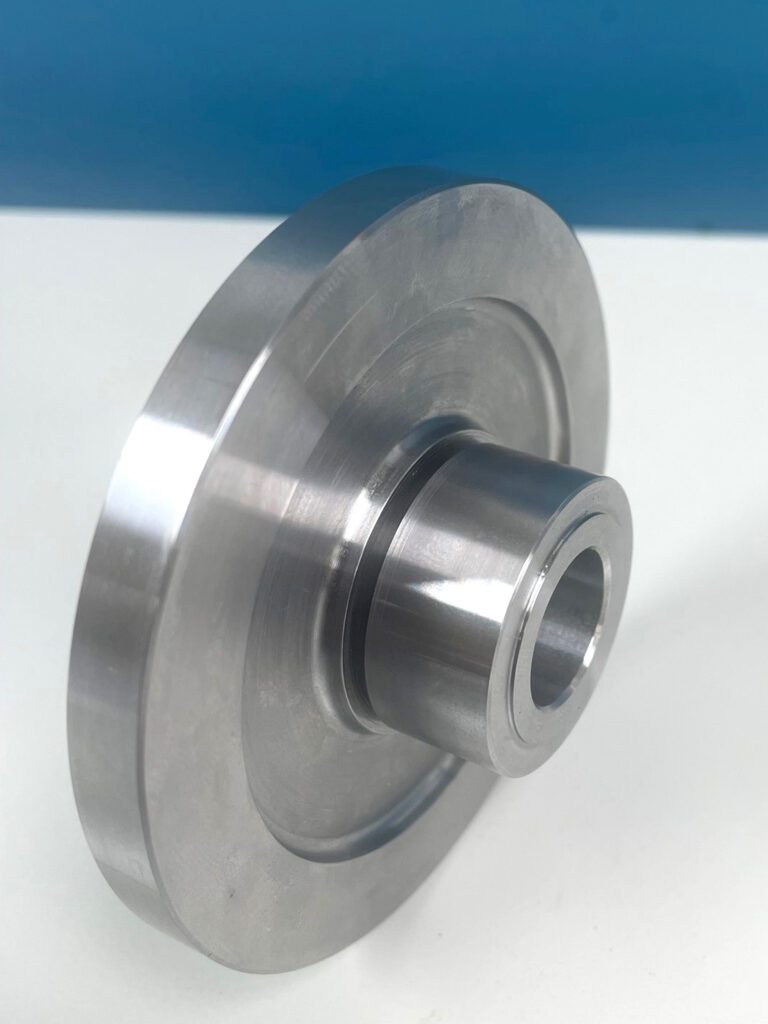

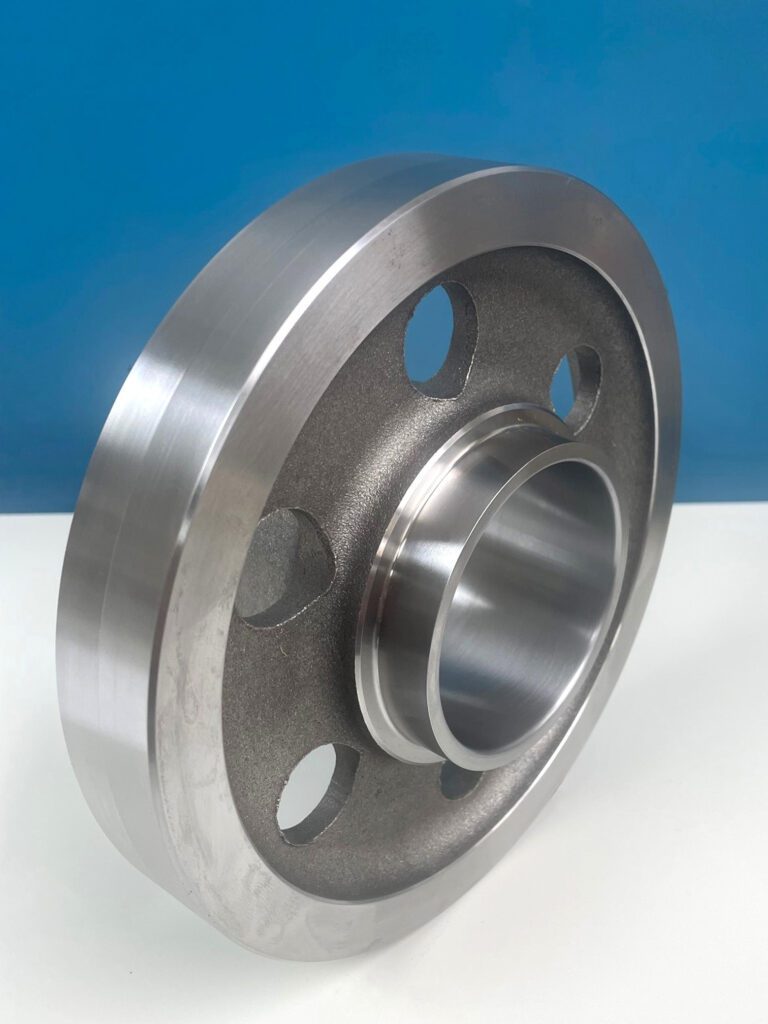

Gear Blank Services

Noble-X produces blanks and shafts used in most gearing applications including spur, helical, bevel and worm gear products. In addition to turning, we typically provide additional features in what we produce such as drilled and/or reamed holes, drilled and tapped holes, oil disbursement features, keyways, part identification markings, etc. Based on your specifications, we can supply fully machined blanks that are ready for your gear cutting and splining operations.

Noble-X machines gear blanks and shafts from bar stock, forgings and castings. Typically, the blanks we produce are turned complete in a cell that is managed by one machinist. This assists us in maintaining consistent control over critical characteristics such as close tolerance linears, parallelism, perpendicularity and runout. We understand what goes into a quality blank and how the work we perform directly affects subsequent processing.

Contact us today about your job!