How AI is Revolutionizing CNC Machining and Fabrication

As the world embraces the era of Industry 4.0, cutting-edge technologies are transforming the manufacturing landscape. One such groundbreaking technology is Artificial Intelligence (AI), which is revolutionizing the field of Computer Numerical Control (CNC) machining and fabrication. Let’s explore the powerful synergy between AI and CNC machining, showcasing how it is reshaping machine shops and empowering us to deliver higher efficiency, precision, and customer satisfaction.

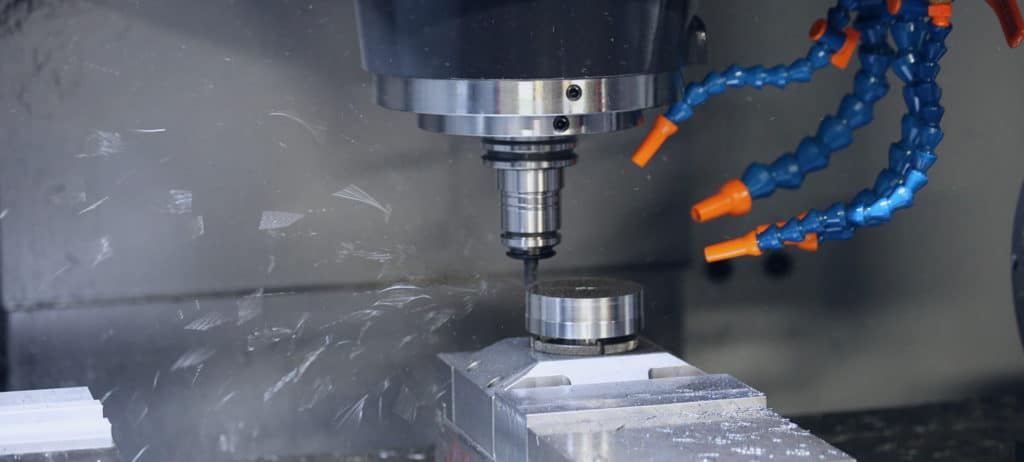

Automated Programming and Optimization

Traditionally, CNC machine programming involved manual writing of G-code instructions, which is time-consuming with a possibility of error. With AI, there could be a paradigm shift. AI-powered Computer-Aided Manufacturing (CAM) software now automatically generates CNC programs from CAD models. Moreover, AI algorithms optimize machining parameters, tool paths, and cutting speeds, resulting in reduced cycle times, improved tool life, and higher-quality outputs.

Smart Predictive Maintenance

Downtime due to unexpected machine failures can adversely impact production schedules and profitability. AI comes to the rescue with predictive maintenance solutions. By analyzing sensor data and monitoring machine behavior, AI algorithms can predict potential failures in advance. This allows operators to schedule preventive maintenance, avoiding costly breakdowns and ensuring seamless production.

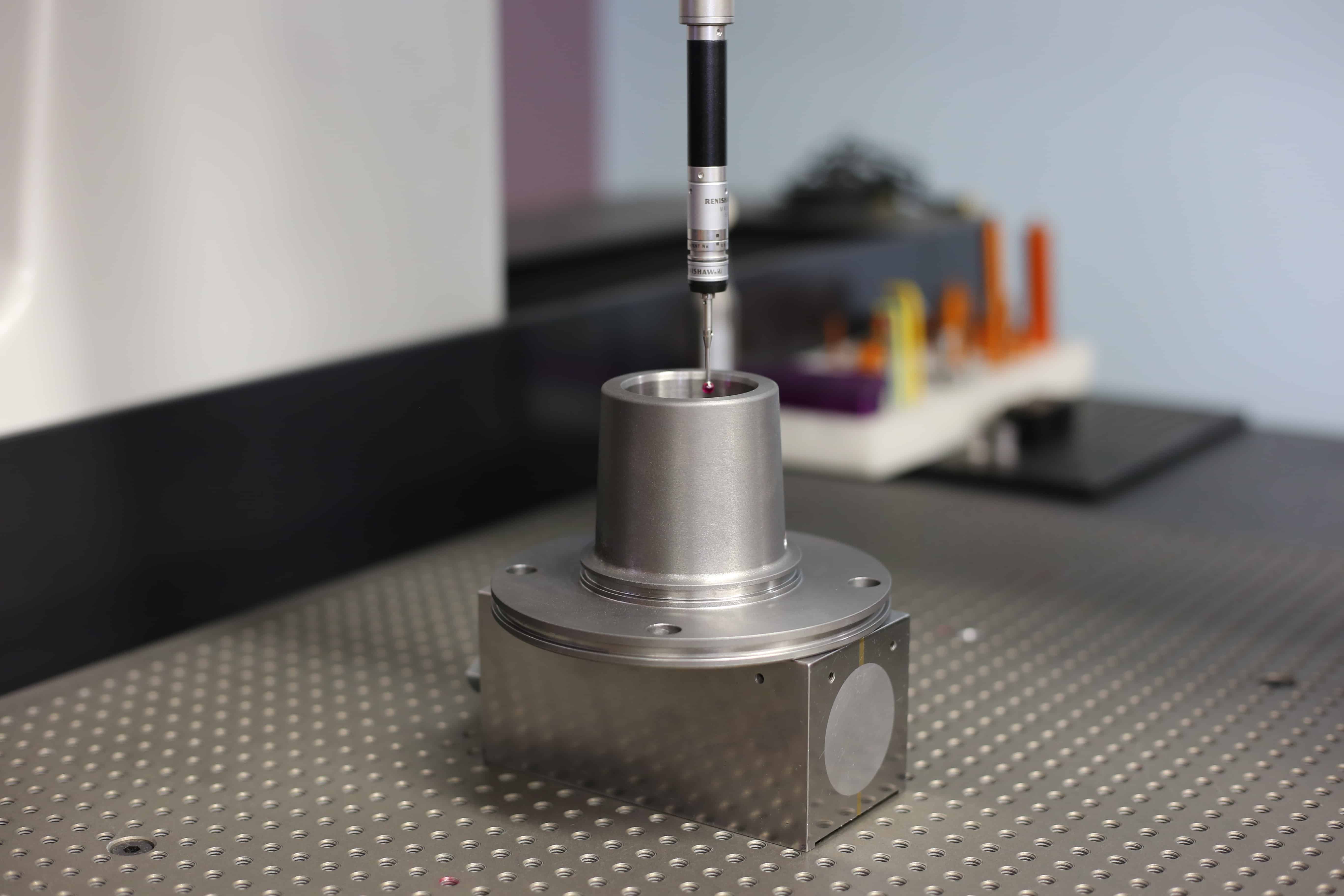

Enhanced Quality Control

In CNC machining, precision and quality are paramount. AI-powered vision systems play a critical role in quality control by performing automated inspections. These systems analyze sensor data and images to detect defects and deviations in real-time. As a result, this can minimize rework, reduce scrap, and ensure consistent quality throughout production.

Training and Skill Development

New machinists can now benefit from AI-powered training and simulations. AI-driven interactive modules and virtual mentors guide them through real-world machining scenarios, accelerating their learning curve and instilling best practices.

By automating programming and optimization, AI streamlines the CNC process, ensuring reduced cycle times, optimized tool paths, and higher-quality outputs. Furthermore, AI’s predictive maintenance capabilities enhance overall equipment efficiency, minimizing downtime, and maximizing productivity across the industry. As AI-powered vision systems take center stage in quality control, manufacturers can ensure precise inspections, minimizing waste and bolstering product consistency. The AI-driven training and skill development foster a skilled workforce, well-equipped to embrace the transformative potential of AI and contribute to the manufacturing landscape’s continued progress. Embracing AI’s potential, the manufacturing industry can deliver unmatched efficiency, precision, and customer satisfaction on a global scale.

Precision Machining: What to Look for in a Manufacturing Partner Precision machining requires a keen eye for detail and top-notch Read more

5 Benefits of Outsourcing CNC Machining Services Outsourcing CNC machining services to a professional shop like Noble-X offers businesses a Read more